Our Machine Tools

Developing original mechatronics systems to support key industries

SAKURAI’s technical capabilities when it comes to in-house production of major machine tool parts, along with our large-scale processing equipment have earned us a high reputation in our field and has solidified our credibility as a manufacturer.

We have cemented a proposal-based approach for everything from single machines to large-scale line systems, and we are proud to say that our products are being used all over the world. We have an in-house integrated production system that spans development, design, production, assembly, and maintenance. This system enables us to reduce the time required to fulfil an order, as well as allowing us to streamline costs.

Reasons to choose SAKURAI

1. Standard machines

We promise to provide machines capable of high precision, high efficiency, high rigidity, and favorable maintenance.

Prominent examples

・Rotary milling machine

・Multi-axis machine (CUBIC/TURREX)

・Deburring machine (B-Trim series)

2. Specialized machines

We offer innovative proposals to customers are seeking to reduce their number of general-purpose machines or who are seeking machines that surpass the functionality of general-purpose machines.

Additionally, we also respond to our customer needs by providing creative ideas in a way only a specialized machine manufacturer can

Machine Tool Production Process

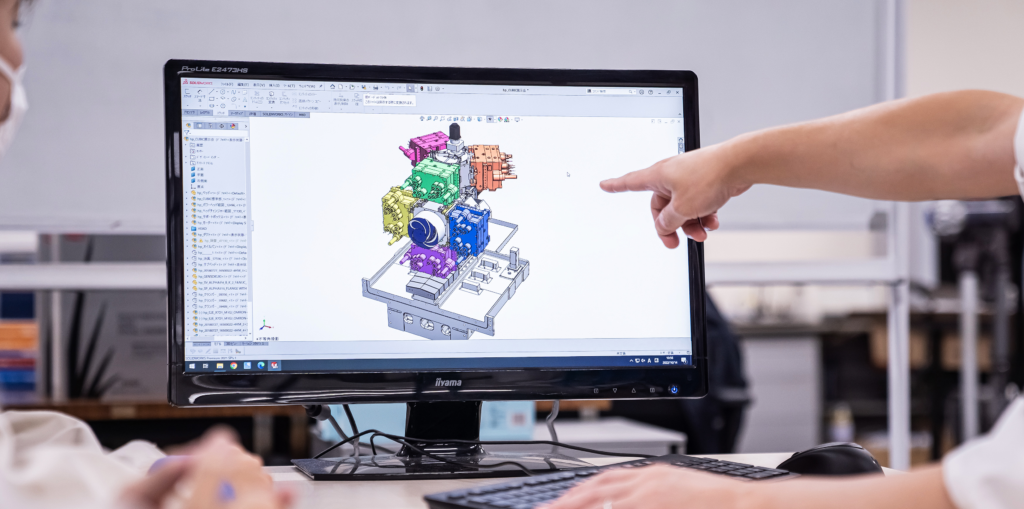

1. Design

By making full use of 3D-CAD, which provides accurate and has excellent visibility, we can identify any potential issues at an early stage through design and design reviews. At SAKURAI we perform product design that ensures high quality and excellent safety.

2. Processing

We have more than 30 types of processing equipment, from large 5-sided processing machines to compound lathes. We make full use of 3D-CAD/CAM systems to achieve highly efficient and highly accurate processing.

3. Assembling

We have a large assembly space where not only individual equipment but also line equipment can be placed. In this space skilled engineers can carefully and quickly assemble each product.

4. Precision measurement

The Quality Assurance Section is responsible for everything from assurance of unit accuracy, assembly accuracy, and workpiece processing accuracy to post-sales follow-ups